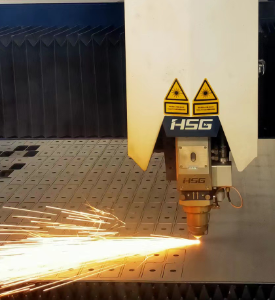

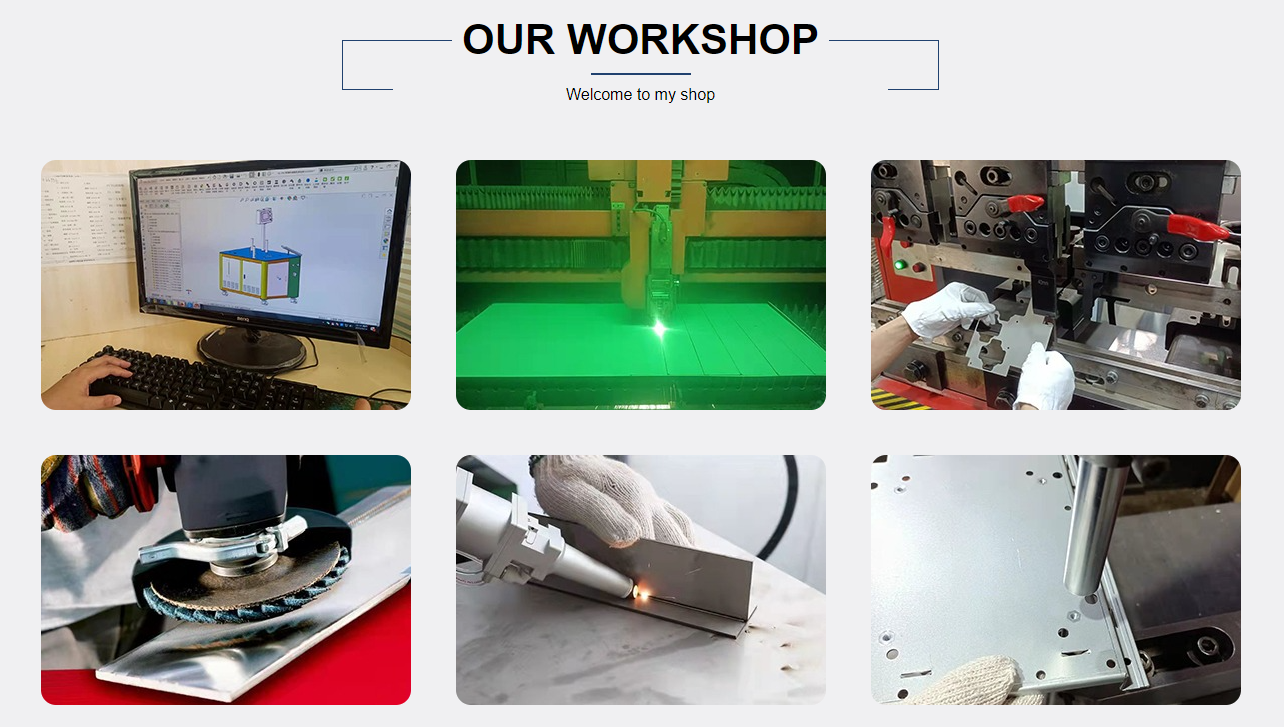

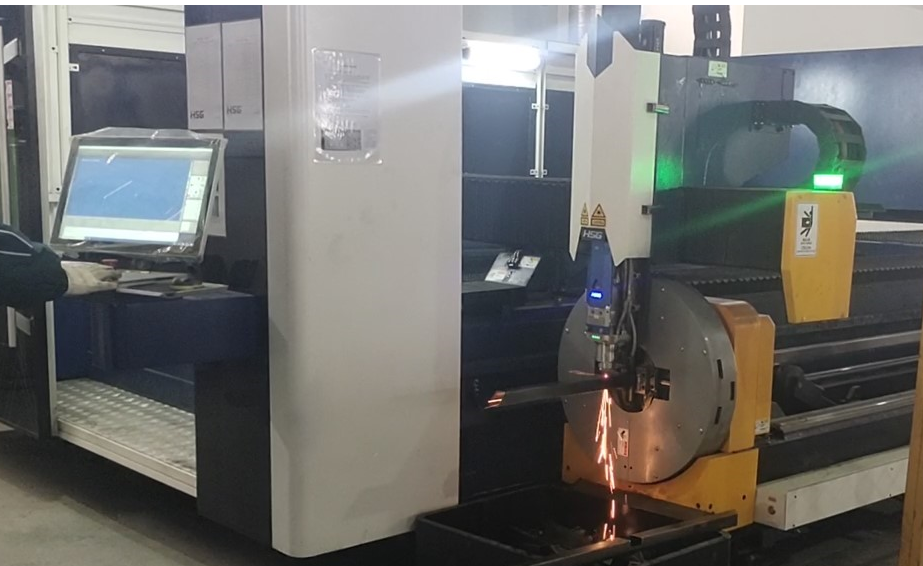

Main Production Equipments:

Laser cutting is a frequently used machine for metal processing and can cut sheet metal, round and square tubes up to a thickness of 18mm or more.

12 sets of 40T presses, 5 sets of 160T presses, 2 sets of 400T presses. it is used for producing stamping parts

CNC bending machine for the production of chassis, metal structure parts, energy storage battery shell, electronic chassis and so on.

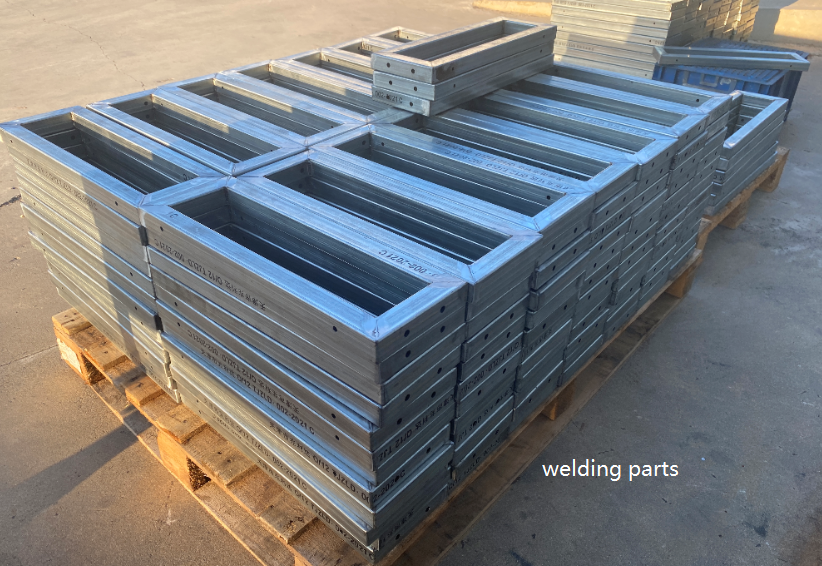

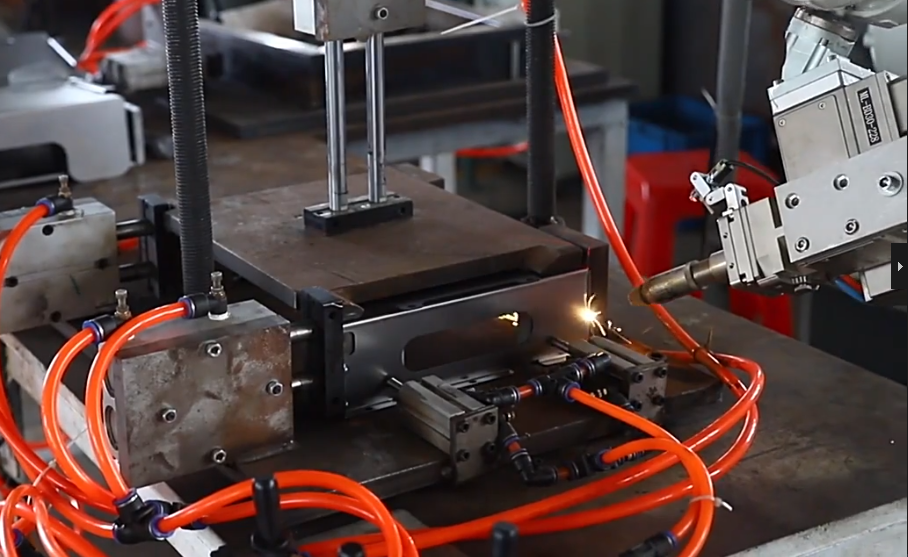

2 welding robots, 2 sets of laser welding machines, 3 sets of MIG welding machines

NC EMTAL is a subsidiary of a 27 year old Cangzhou Tianhua company, it is located at Nanpi County, Cangzhou City of China,where is famous for hardware production. we are engaged in stamping parts,sheet metal fabricationt,metal structure parts,sheet metal housing, sheet metal processing, battery storage housing, chassis,CNC part and welding part,we provide custom product services.

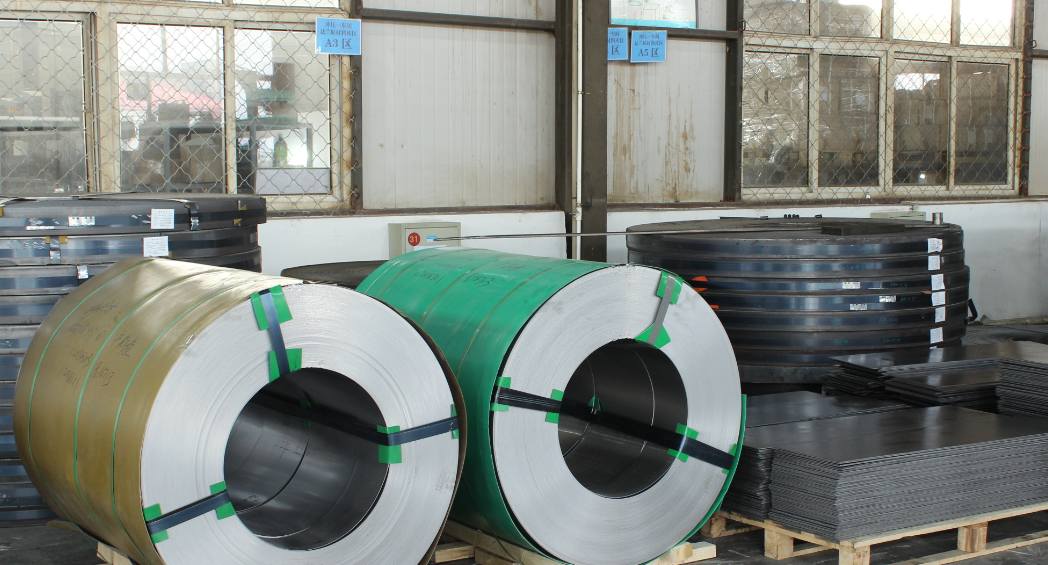

We can make products with materials of stainless steel, steel alloy, copper, aluminum, etc. The surface treatments we can handle include anodize, black oxide, powder coating, high polishing and plating. In order to make sure the critical dimensions, we import our machines from the USA and Japan. The minimum tolerance we can make is 0.01 millimeter. we have 46 employs,our engineers are quite experienced and could give some advice when you need.Our workers are well-trained and follow ISO (IATF16949:2016)standard.

we are experienced in export foreign trade business.We hope to work together with you to make it happen and grow up stably.It is our pleasure to support you to be stronger and do better in your market.

NC METAL core team members come from the automotive parts manufacturing industry and have a rigorous approach to product quality control and customer service. Our work is carried out in accordance with the IATF 16949:2016 quality management system.

we strictly implement the process quality control and quality inspection procedures.Customer satisfaction is the primary pursuit .

For product delivery requirements,quality and technical details, we will confirm with customers until there is no deviation in understanding, and fully meet your requirements.

After completing the first few samples, we conduct a quality inspection of the samples and if defects are found in the samples, we will fully resolve the problems before we proceed to mass production.