we accept customizied sheet metal bending parts, cabinet,metal housing, battery storage housing, chassis,electric enclosure.

We have 12 sets of 40T presses, 5 sets of 160T presses, 2 sets of 400T presses and we design and develop stamping dies by ourself. Our company is located in Cangzhou City, China, the famous home of hardware stamping, and we are professional.

We have dedicated welding shops and workers, as well as welding robots, including laser welding,TIG and MAG/MIG welding. We carry out quality checks on the depth of weld. We make strong and beautiful welds.

Metal stretched parts are technically demanding and we perform CAE analysis on difficult parts to confirm that the amount of stretch thinning is controllable.

We implements the IATF 16949:2016 Quality Management System.

we believe:reliable product quality, good service quality and customer satisfaction are the foundations of long-term cooperation.

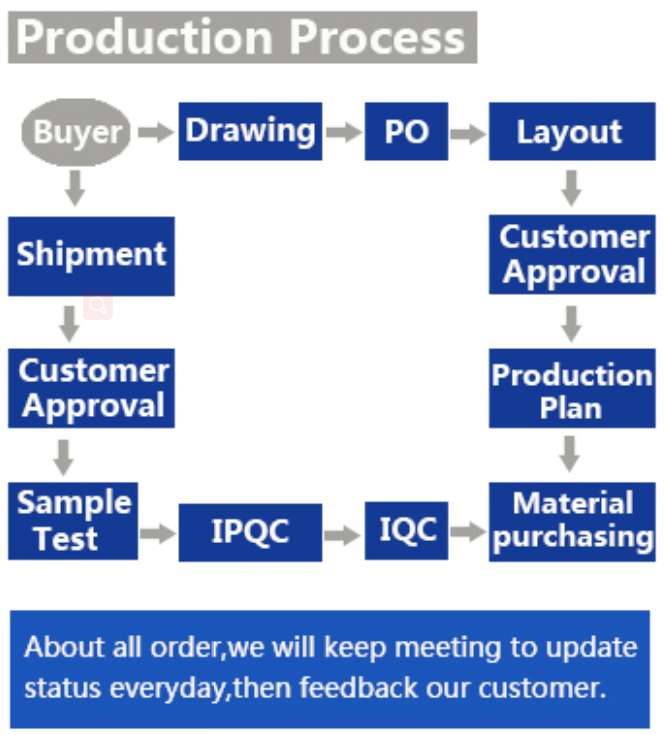

We identify the special requirements of our customers in terms of appearance, dimensions, assembly tolerances, packaging methods and even shipping requirements. These special requirements are documented and implemented during the production and delivery process.

We carry out a DFM analysis of product drawings based on software technology and the experience of our engineers. If any requirements are found that cannot be met, we will discuss them with the customer and make technical improvements to the design.

Quality checks are carried out on raw materials before they are put into storage. During the production process, quality checks are carried out in accordance with the work instructions and at the required frequency.For all exports, we carry out a 100% visual inspection.

After completing the quality inspection of the product, the correct packaging solution is adopted to prevent scratching, dropping and rusting. To ensure that the products delivered to the customer are in perfect condition.